In-house development for improving efficiency

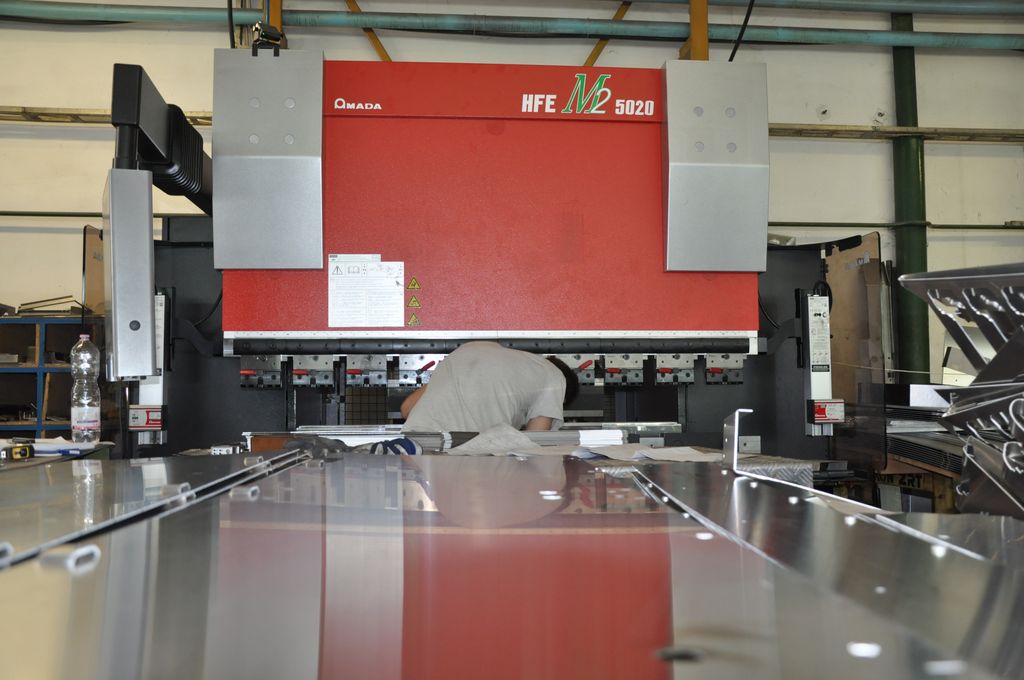

As we reported earlier, our company has carried out welding technology development via tender, and besides that, with our own resources, we have purchased a bending press brake and a pallet changer for the already operating laser cutting machine.

Due to its special beam and column design, the japan made AMADA HFE M2 bending press brake automatically provides cambering without the need of additional control and manual adjustment.

Among other things, the machine is equipped with AMADA NC AB PAD graphic touch screen controller, electric foot pedal and emergency stop function.

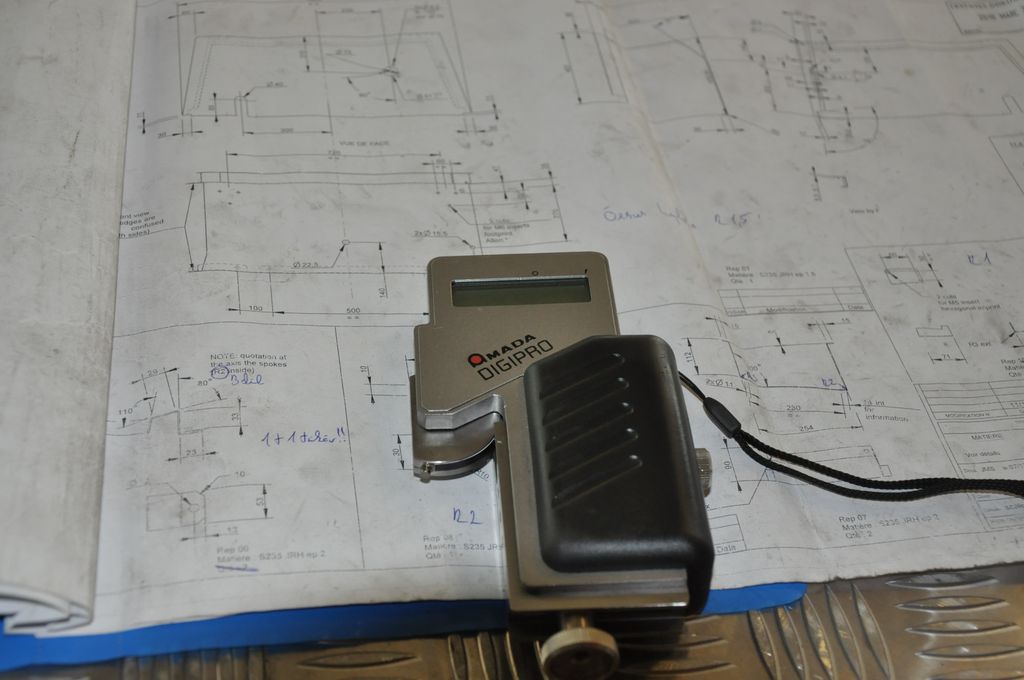

Working operation can be performed from memory or directly from USB. A munkavégzés végrehajtható memóriából vagy közvetlenül USB-ről.

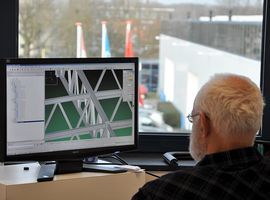

With AMADA BEND SOLUTION PACK software belonging to the system, the technologist can prepare the bending program in advance at the office. Dies and bending order can be specified for a given component or even for a complete assembly, and simulations can be done in 3 dimensions to ascertain if everything is perfect, for example, there is no collision.

For more efficient utilization of the TruLaser 1030 fiber laser cutting machine, our company has also purchased a pallet changer, which results in less no-load running of the machine.

Due to the pallet changer, it is possible to remove the already cut parts and to prepare the raw material for the next cut during the actual cutting process.